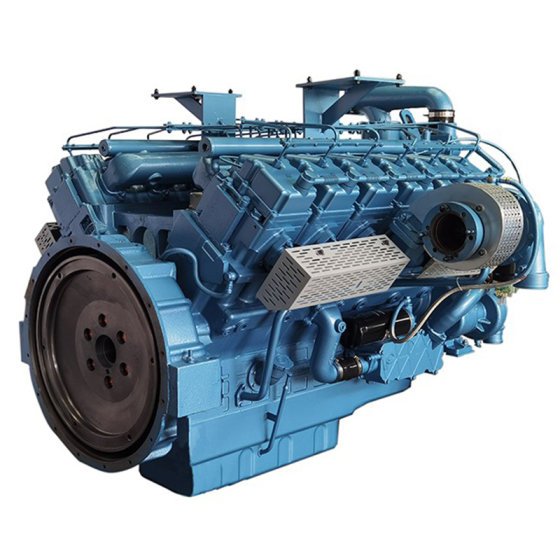

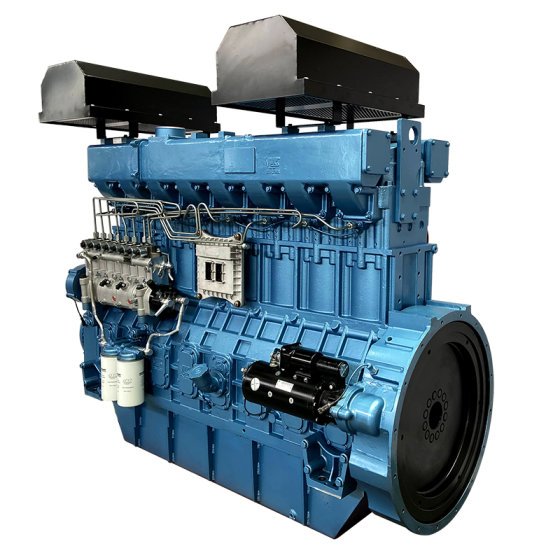

KR8Z34D1230G3-5 1230kW Diesel Engine

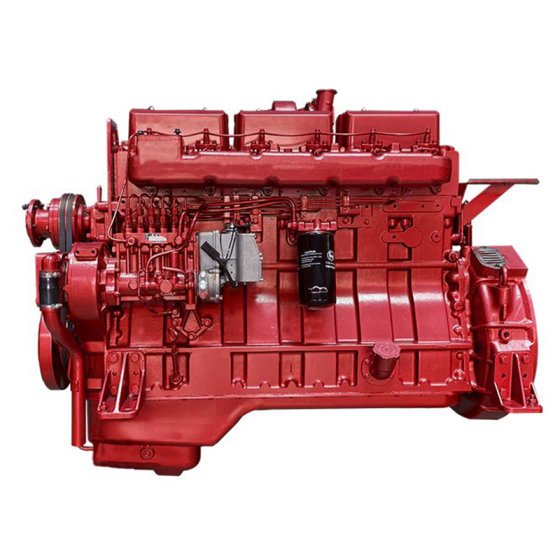

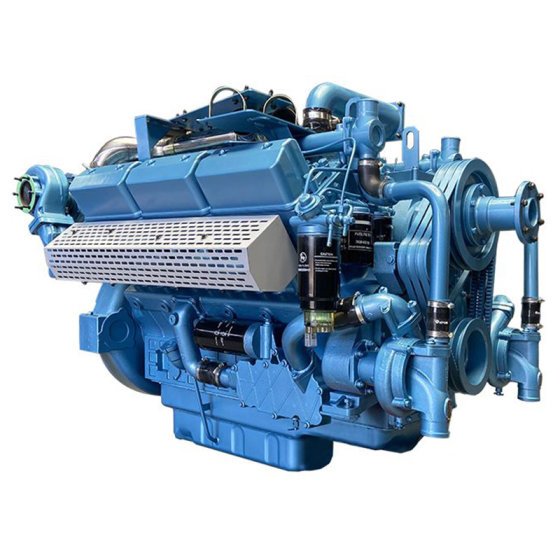

KR8Z34D1230G3-5 1230kW Diesel Engine. These engines include non-road diesel engines, marine diesel engines, alternators and generator sets, which, as part of the main generator or standby power supply, are often used in communication, railway, oil, airports, hospitals, field exploration and other applications.

KR8Z34D1230G3-5 1230kW Diesel Engine. These engines include non-road diesel engines, marine diesel engines, alternators and generator sets, which, as part of the main generator or standby power supply, are often used in communication, railway, oil, airports, hospitals, field exploration and other applications.

KRZ series diesel engine is a new product independently developed by KOKURO Power SOLUTIONS. It integrated advanced technologies from Japan and China and abroad and represents a series of technological innovations. It includes four-valve, low-vortex air passages, oil and gas balance, efficient cooling, low weight, and highly integrated compact design. They can be electronically controlled, upgrade to include and other technologies such as CPUs. This series is designed to take into account high-intensity usage; it can reach a maximum burst pressure of 18MPa. With the same displacement, the model has achieved a 15% increase in power over other products, with 18% smaller volume and 16% lighter weight. It provides uses with a new generation of high-quality engine products that are reliable, fuel-efficient, Lowe-cost, and meet emission requirements.

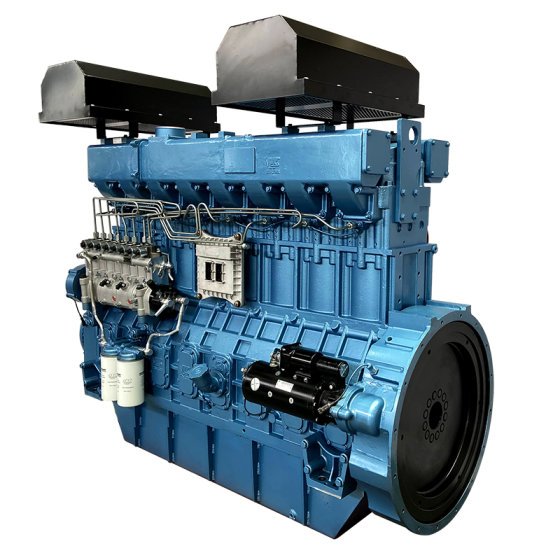

Specifications:

| Model | SY8Z34D1230G3-5 |

| Bore (mm) | 160 |

| Stroke (mm) | 210 |

| Type | inline, 8 cyliners, direct, injection, 4-stroke |

| Aspiration | Turbocharged with Intercooler |

| Compression Ratio | 14.5 |

| Displacement (L) | 33.78 |

| 1h Power (kW) | 1230 |

| Min. fuel consumption (g/kW.h) | 190 |

| Oil consumption (g./kW.h) | ≤0.4 |

| Idle Speed (r/min) | 650 |

| Rated Speed (r/min) | 1500 |

| Interface | SAE 0#/18″ |

Engine package weights and dimensions

| Length | 2158mm |

| Width | 1004mm |

| Height | 1723mm |

| Weight(Dry) | 3300kg |

-Equipped with an electronically controlled fuel injection system on the basis of the stage 2 emission regulation to achieve stage 3 emission regulation.

-Using the electronic control combined unit pump technology, according to the work needs, punctual , quantitative and uniform fuel injection , high combustion efficiency, reduced emissions and noise, improved fuel economy, and low fuel consumption.

Adopt 4-valve technology to increase air intake and greatly increase diesel engine power

Reduce fuel consumption

Oil and gas balance: the balance chamber is designed to reduce pumping loose and reduce fuel consumption. Efficient cooling: the tangential inlet waterway design reduces cooling area of the water jacket in the cylinder liner, and increase the flow rate of the cooling water, thereby reducing the cooling power consumption.

Efficient cooling: the tangential inlet waterway design reduces cooling area of the water jacket in the cylinder liner, and increase the flow rate of the cooling water, thereby reducing the cooling power consumption.

Lightweight: high-strength materials are sued to maximize power while still ensuring engine reliability. Highly integrated compact design” the internal pipe structure design reduces the profile of the product .resulting in a more compact and modern appearance, in addition to reducing possibility of leakage.